Alco Gravure printing Midland is a precise method that uses engraved cylinders to transfer ink onto materials like paper, plastic, or fabric. Its ability to produce high-quality prints is ideal for large-scale projects like packaging, magazines, and labels.

This article looks at how Alco Gravure Printing has made a name for itself and why it is a leader in the printing business.

What is Alco Gravure Printing Midland?

Alco Gravure Printing Midland is a company that provides top-notch gravure printing services. This type of printing uses engraved cylinders to transfer ink, making it perfect for detailed and sharp prints. It is often used for large projects like magazines, packaging, and labels.

Many businesses choose Alco Gravure Printing Midland for its reliable results, precision, and ability to handle big orders efficiently.

Alco Gravure Printing Midland Technology

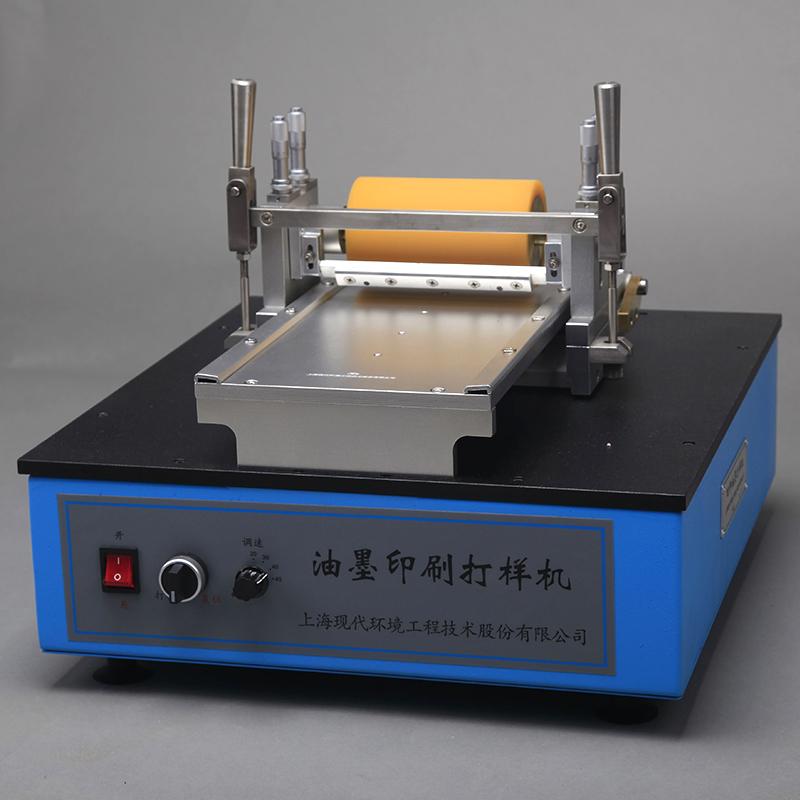

Cylinder Preparation:

In this process, the printing cylinders are engraved with tiny cells that hold ink. These cylinders are carefully prepared to ensure detailed and clear prints. The precision of cylinder preparation is key to achieving high-quality results, making it ideal for large-scale printing like packaging and magazines.

Inking Process:

In the Alco Gravure Printing Midland inking process, ink fills tiny cells engraved on the printing cylinder. As the cylinder rotates, it transfers the ink onto materials like paper or plastic.

This creates sharp, detailed prints. The inking process is carefully controlled to ensure even coverage, making it perfect for producing high-quality, large-scale prints.

Printing and Drying Steps:

In Alco Gravure Printing Midland’s printing and drying steps, the prepared cylinder rolls over the material, transferring ink to create clear images.

After printing, the material goes through a drying process, where hot air or heat lamps help the ink dry quickly. This makes sure the prints are bright and ready to use without any smudges.

Read Also: M Mkme33ee – Understanding High Techniques In 2024!

How Does Alco Gravure Printing Midland Work?

Alco Gravure Printing Midland works by using specially engraved cylinders to print images on materials like paper or plastic. First, the cylinders are prepared with tiny cells that hold ink. The cylinder rolls over the material, transferring ink from the cells to create clear prints.

After printing, the material goes through a drying process to set the ink quickly. This method allows for fast and high-quality printing, perfect for large projects.

Why Alco Gravure Printing Midland Is Important for Businesses?

Gravure Printing Midland is important for businesses because it offers high-quality prints that are the same every time and very trustworthy.

This method ensures that every printed item looks the same, which is vital for packaging and magazines. It is also cost-effective over time since engraved cylinders can be reused for many prints.

Additionally, it can print on various materials, giving businesses the flexibility to meet different needs while enhancing their brand’s appeal.

Read Also: Immediate Serax V3 – A Comprehensive Guide!

Advantages of Using Alco Gravure Printing Midland

Using Alco Gravure Printing Midland offers several advantages. First, it provides high-quality prints with sharp details and vibrant colors. Second, the printing process is efficient, allowing for large quantities to be produced quickly and consistently.

Third, it is cost-effective because engraved cylinders can be used for many runs. Additionally, this method can print on various materials, making it versatile for different business needs, such as packaging, labels, and magazines.

Types of Products Created with Alco Gravure Printing Midland

They create various products for Alco Gravure Printing Midland. One main type is packaging, including labels, boxes, and wraps for food and cosmetics. It also prints magazines and catalogs with clear pictures and easy-to-read text.

Another product is wallpapers, where detailed designs and colors are printed for home decoration. Additionally, Alco Gravity Printing makes stickers and labels for beverages and household items. This versatility helps businesses meet many printing needs effectively.

Comparing Alco Gravure Printing Midland to Other Printing Methods

The Alco Gravure Printing Midland to other printing methods shows several advantages. Unlike digital printing, gravure offers higher quality and consistency for large print runs. While offset printing is good, gravure excels in producing vibrant colors and fine details.

Gravure printing is also more efficient for high-volume jobs, as the engraved cylinders can be reused. Overall, Alco gravure printing is a reliable choice for businesses needing high-quality prints quickly and cost-effectively.

The Role of Technology in Alco Gravure Printing Midland

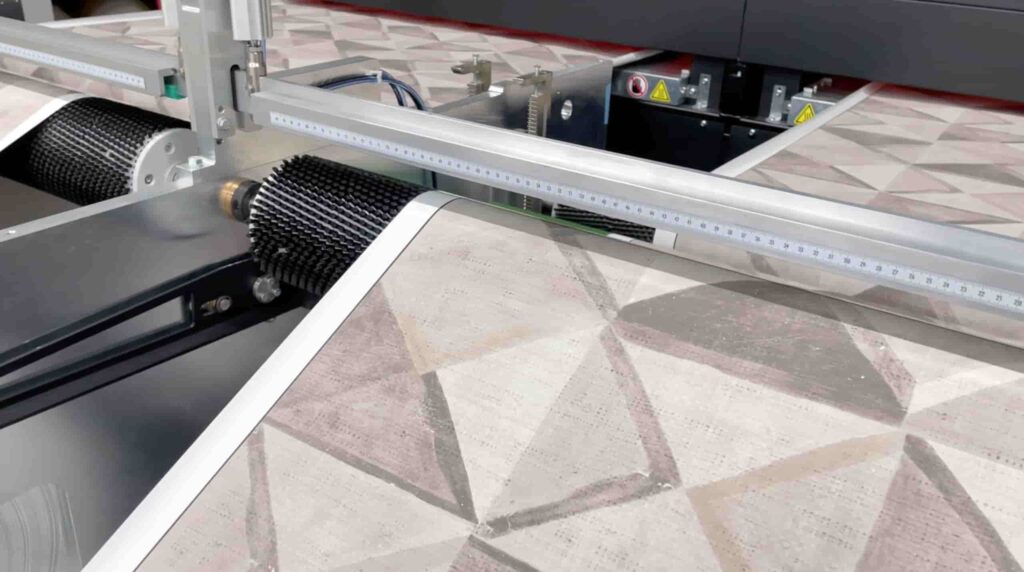

Technology plays a key role in Alco Gravure Printing Midland. It starts with advanced engraving machines that create precise patterns on the printing cylinders. Modern printing presses ensure fast and consistent ink transfer, producing high-quality prints.

Also, fast-drying systems use hot air or UV light to dry the ink quickly. These technologies improve speed and quality, allowing businesses to produce large volumes of printed materials reliably and cost-effectively.

How Does Alco Gravure Printing Midland Improve Print Quality?

They enhance print quality at Alco Gravure Printing Midland in many ways. First, the detailed engraving on the printing cylinders ensures that images and text are sharp and clear. This is important for making products look professional.

Second, the use of the same cylinder for each print provides consistency, meaning every copy looks the same. Finally, high-quality inks create vibrant colors that match the original design, which is essential for eye-catching packaging and marketing materials.

Alco Gravure Printing Midland in Packaging and Design

Alco Gravure Printing Midland is very important for packaging and design. It produces high-quality labels, boxes, and wraps that attract customers with sharp images and bright colors. The ability to print on different materials, like plastic and foil, makes products stand out on store shelves.

Additionally, the consistent quality ensures that every package looks professional. This helps businesses create a strong brand image and effectively communicate their product’s value to consumers.

Environmental Impact of Alco Gravure Printing Midland

It’s important to think about how Alco Gravure Printing Midland affects the environment. The company uses advanced technology to reduce waste and improve efficiency. Many modern inks are eco-friendly and less harmful to the environment.

Additionally, gravure printing produces less waste compared to other methods, as it can print large quantities at once. By focusing on sustainability, Alco Gravure Printing helps businesses meet their printing needs while protecting the planet for future generations.

How to Choose the Right Alco Gravure Printing Midland Services?

To choose the right Alco Gravure Printing Midland services, start by looking for a company with experience in gravure printing. Check if they have the right equipment for high-quality results.

Consider the specific products you need, like packaging or magazines, and ensure the company specializes in that area. Lastly, read reviews and testimonials from past customers to gauge their reputation. This research will help you find a reliable printing service that meets your needs.

Future Trends in Alco Gravure Printing Midland Technology

Future trends in Alco Gravure Printing Midland technology include a focus on eco-friendly practices, such as using water-based inks and energy-efficient machines. These changes help reduce the environmental impact of printing.

Another trend is the integration of digital technology, which enhances the engraving process for better detail and accuracy. These advancements will make gravure printing more efficient and effective, helping businesses produce high-quality prints that meet modern demands and stand out in the market.

Frequently Asked Questions:

1. What is the difference between gravure and offset printing?

Gravure printing uses engraved cylinders to transfer ink, allowing for high-quality, detailed prints, especially in large quantities. In contrast, offset printing uses flat plates and is better for smaller jobs, offering good quality but usually with less detail than gravure.

2. How does Alco Gravure Printing handle environmental concerns?

Alco Gravure Printing addresses environmental concerns by using eco-friendly inks, like water-based options, and energy-efficient machines. They also focus on reducing waste during the printing process, helping to protect the environment while still delivering high-quality prints for businesses.

3. What types of materials can be used in gravure printing?

Gravure printing can be used on different materials like paper, plastic, foil, and fabric. This flexibility allows it to produce high-quality prints for packaging, labels, magazines, and decorative items, making it suitable for many industries and applications.

4. How does the cost of gravure printing compare to digital printing?

Gravure printing is cheaper for large quantities due to lower costs per print, while digital printing is better for small jobs since it has no setup costs and is more flexible.

5. What are some examples of successful Alco Gravure Printing projects?

The successful Alco Gravure Printing projects include vibrant packaging for consumer products, high-quality magazines, detailed wallpapers, and colorful labels for beverages, all showcasing the method’s ability to deliver excellent results consistently.

Conclusion:

In conclusion, gravure printing is a great way to make high-quality prints for different products, like packaging and magazines.

Its consistency, versatility, and cost-effectiveness make it a trusted choice for businesses, ensuring vibrant designs that meet large-scale printing needs while maintaining excellent quality.